As the Christmas rush begins in earnest with consumers encouraged to buy gifts early thanks to premature discounting and offers, it is easy to forget that retailers have been preparing for the event for months, putting systems in place to ensure that items arrive to shoppers in good time.

In recent weeks, a multitude of retailers, from Marks and Spencer to Amazon, have announced the recruitment of thousands of additional Christmas staff in order to cope with the festive peak, with the likelihood that a majority of temporary staff will be kept on full time to create a larger talent pool and offer a return on investment for training costs.

While additional manpower is the traditional response to busy periods, the rapidly increasing presence of specialist software within the retail sector leads many to believe that implementing technological measures to control the supply chain is now easier than ever.

“Technology has traditionally played an essential part in the supply chain process and the ecommerce space as a whole, but as we all move rapidly into m-commerce and omnichannel, technology is becoming the star of the show,” Mark Needham, Operations Director of logistics firm iForce, told Retail Gazette.

“As in any industry, expectations of technology performance are higher now than ever. Technology creates a new world for retailers and has created a true multichannel offering.

“With the advent of mobile alerts to the consumer throughout the delivery process – visibility is key to the consumer, and made possible through smart technology.

“The online space is a very vibrant one, and is growing by around 20-30 per cent a year. Agile technology is making this happen.”

iForce offers tailored solutions to the industry service and uses a proprietary system to plug into retailers‘ systems which allows updated information on warehouse management, stock visibility and replenishment as well as data analysis and the firm works with retailers including John Lewis and Sainsbury‘s.

Undoubtedly though, such a broad spectrum of retailers have varied requirements when it comes to supply chain preparation as many sub-sectors, such as fashion, create fast-paced environments heavily based on seasonal trends.

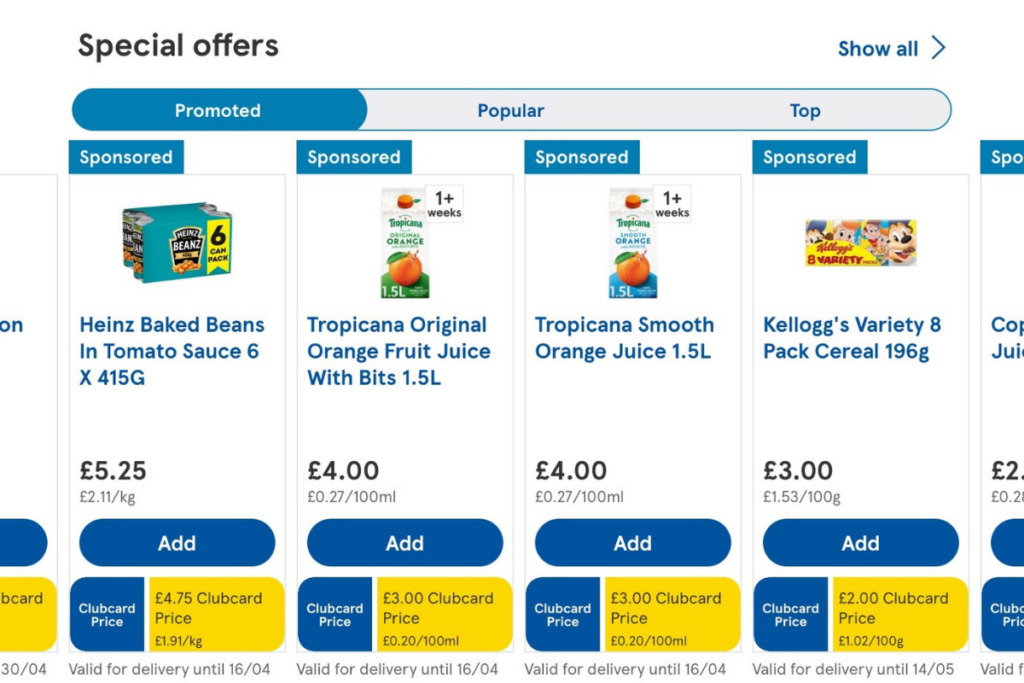

Meanwhile, the grocery sector is comparatively easy to predict with a peak generally taking place in the final fortnight before Christmas, while a majority of food goods are sourced locally to allow for quick responses to demand.

Industry supplier JDA highlighted the importance of sourcing goods locally to reduce waste and improve delivery times.

“We are starting to see more retailers recognise the need for a responsive supply chain, which is challenging the strategy for exclusive overseas sourcing,” Lee Gill, Vice President of Retail Strategy EMEA at JDA told us.

“In recent years many had traded flexibility for cost savings; now retailers are realising that there needs to be a better balance between local and international sourcing.

“From the technology perspective, JDA is helping retailers by providing them with complete visibility of where inventory is at any point in the supply chain so they can better understand lead times.

“Clever demand forecasting capabilities are imperative as retailers must be able to respond quickly to ever-changing market conditions, especially in today‘s multi-channel world and coupled with this is the need for a good assortment planning tools.

“Ultimately, all of this will allow retailers to make better informed decisions regarding their sourcing strategy and to make the necessary changes to their supply chain.”

Such cutting edge capabilities are clearly having a positive effect on retailers output given the rise of fast fashion and the heightened expectations of the ever-connected consumer. As the need for an omnichannel presence sweeps the sector, retailers have been

RELATED STORIES