Before the coronavirus outbreak, the fashion retail sector and its supply chains were far from perfect. Yet the pandemic has shined a spotlight on the glaring issues within, with the controversy surrounding modern slavery allegations levelled at Boohoo Group last year being a shining example.

Leonie Barrie, apparel analyst at GlobalData, highlighted five key issues that are rewriting the rules on apparel sourcing for fashion retail. These included building greater resilience in sourcing networks, rebalancing apparel supply chain, embracing strategic supply partnerships, fast-tracking digital investments, and end-to-end visibility.

So how exactly can fashion retailers begin to achieve these in their supply chains going forward?

“If fashion retailers want to shore up their supply chains, adapting their supply chain design and the flows within continuously to the changes in the macroenvironment is key,” said Madhav Durbha, group vice president at supply chain solutions provider LLamasoft.

“In today’s world, creating a supply chain that is flexible and resilient to disruptions relies on having the right technology.

“Fashion retailers must look to leverage technology”

“Technology such as digital twin technology allows companies to digitally replicate their supply chains and virtually simulate its agility and resilience, before implementing it in the real world.”

Madhav explained that with this, fashion retailers can rapidly create supply chain contingency plans to overcome unexpected disruptions.

“By implementing this technology into their supply chains, fashion retailers can ensure they are constantly meeting demand without creating excessive waste,” he added.

“This is a more sustainable and profitable approach to supply chain strategising.”

While there have been calls for retailers to make changes to their supply chains, some experts are still sceptical.

Sean Sherwin-Smith, general manager at the AI technology platform HelloDone, said he hadn’t seen an “major step changes being implemented yet”.

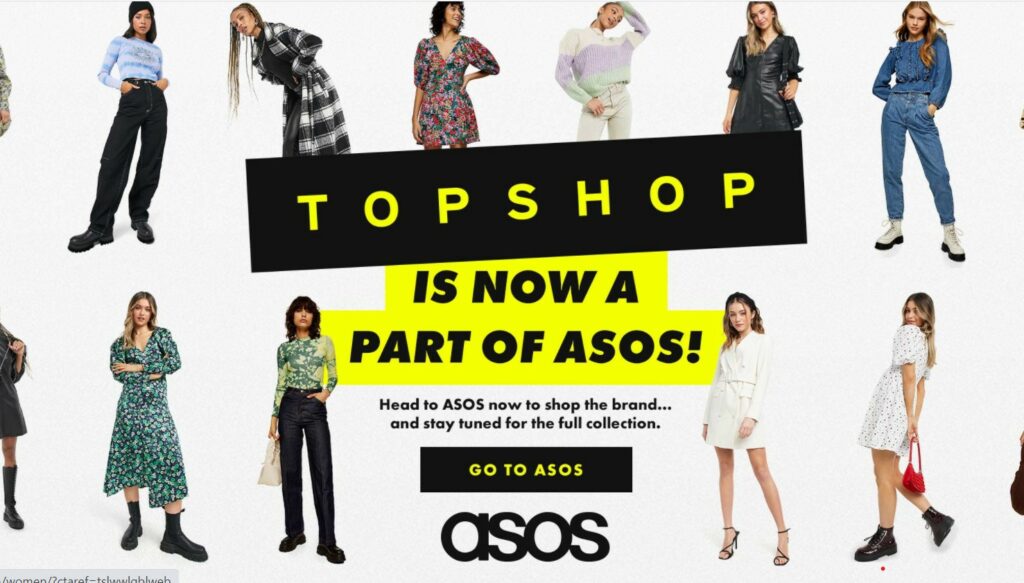

“We have seen Boohoo and Asos swoop in to save big name high street retailers in their darkest hour but their interest is purely digital and likely a bid to gain greater buying power to keep costs (artificially) low,” he told Retail Gazette.

“We also hear that retailers are going through a journey of ‘digital transformation’. But in many cases, this is about ‘keeping up with the Joneses’ rather than thinking holistically about what the future looks like.”

Sherwin-Smith also explained why some retailers could be struggling more than others during this time, saying that it could be down to issues with their supply chains.

“The industry, by its very nature, changes rapidly and makes it very difficult to continually drive success – unless of course, you are cutting corners.

“Making small but continual improvements to the supply chain is what will quickly show results. For example, a very simple exercise is to analyse the reason why items are returned to eliminate toxic products or at least to stop promoting these products and accelerating losses.

“It might sound simple but it’s amazing how many retailers overlook the simple ideas – every retailer has the information they need to seed these sort of transitions and make sustainable decisions, but too often they are drowning in data and starving for insights.”

Back in July last year, Boohoo Group became embroiled in modern slavery controversy when it was alleged that its garment workers in Leicester were paid as little as £3.50 an hour. According to The Sunday Times, a factory in Leicester that supplied Boohoo was also operating during localised lockdowns without additional hygiene or social distancing measures in place.

Following the news, there was demand for fast fashion retailers to prioritise workers’ rights. But is it possible for retailers to strike a balance between being responsible and being efficient?

“Over the recent years, fashion supply chains have become more diverse, reducing overreliance on one country,” Durbha said.

“However, this introduces additional risks. Suppliers engaging in child labour or another releasing pollutants into rivers will have major repercussions on the brand reputations.

“Fashion businesses need to take increased accountability for ethical as well as business reasons”

“Government regulation, especially amongst the European countries is also tightening and claims and damages can be quite punitive beyond the brand impact.

“Supply chain and sourcing will need to work together more closely than ever before to strike the right balance between profit, risk, and resiliency.

“While supply chain teams over the years have built competencies in driving efficiencies, partnering with sourcing allows them to significantly reduce the risks to the supply chain without adverse cost impact.”

Loop Cashmere co-founder Richard Levin said: “Consumers are increasingly concerned with where their clothes come from, how they were made, how well the people making them are treated and how they get to them.

“Retailers need to take accountability for their supply chains and ensure they are being as responsible and sustainable as possible, whilst being resourceful and running a successful business – a challenge that all brands in the industry must overcome to future proof themselves.”

Richard added that during these challenging times, retailers who are looking to improve their supply chain “should treat suppliers in exactly the same way as you treat your colleagues.”

“With the only difference being that you don’t see them in the flesh very often – but that’s something we’re all becoming used to.”

Click here to sign up to Retail Gazette‘s free daily email newsletter