This year‘s London Fashion Week has cemented the ‘see now, buy now‘ trend as a dominating force in the future of fashion retail.

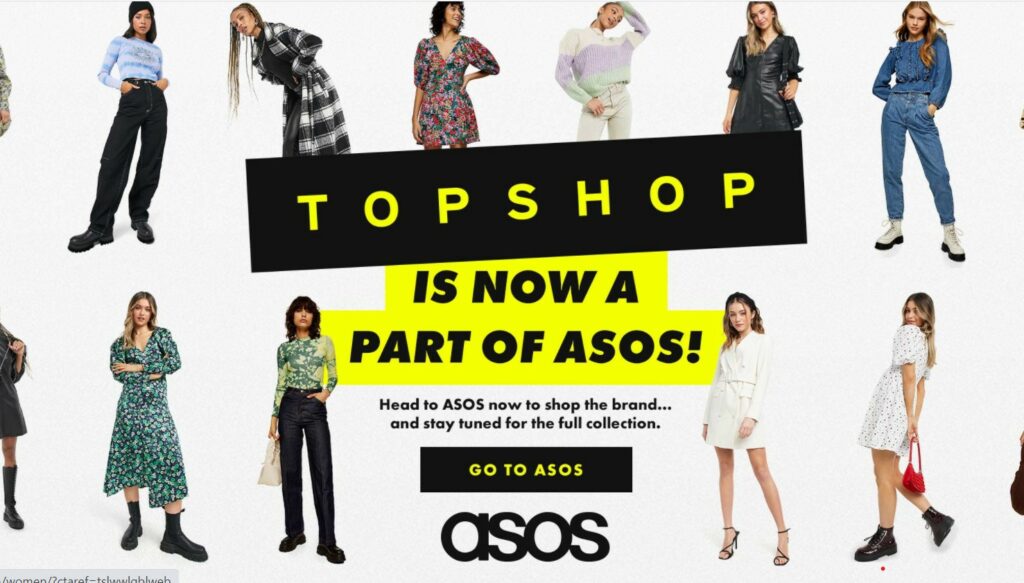

With the likes of Burberry and Topshop releasing collections for sale immediately after their unveiling on the runway, it seems only a matter of time before others follow suit. However, while this move is undoubtedly a shrewd reaction to the impatient demand of the modern consumer, shifting production timelines in this way presents a number of challenges in the supply chain – both high fashion and high street brands must take steps to speed their route to market and achieve the flexibility required to remain on trend.

To ensure garments seen on the catwalk are immediately available to purchase, Burberry has had to significantly modify its product lifecycle, beginning with design of the collection back in January, sampling taking place during February, March and April, and buyers and press being given restricted access to the collection during July. While these steps, as well as the creation of marketing collateral, are essential for the products‘ September release, this business model brings with it a number of specific challenges.

In order to ensure that designs are not leaked and copied by rivals, businesses must establish a relationship of trust with their suppliers. While contractual agreements will typically be put in place, including non-disclosure agreements (NDAs) and punitive clauses that are activated in the event of an information breach, prevention must also be prioritised. This can be achieved by clearly communicating necessary security measures with suppliers and making sure that staff are given the required training to maintain due diligence.

RELATED: Will London Fashion Week ever be the same again?

Priming products for release straight after London Fashion Week is likely to make it more difficult to forecast demand for the new collection, as volumes are ordered from suppliers before there is any critical reaction to base decisions on. This increases the risk of either too little stock being produced, leading to a missed business opportunity, or creating a surplus of stock which must then be disposed of at a discount, diminishing margins. To combat this, businesses should aim to gather prior feedback from consumers via confidential forums, or should ensure that their suppliers are agile enough to facilitate the reordering of the most popular lines.

The move towards fashion immediacy is already filtering through to the high street, and some mainstream retailers such as Zara are demonstrating supply chain flexibility. Several years ago, Zara took steps to shorten its supply chain; moving production to North Africa in order to replenish its offering in-season and react to the latest trends showcased on the runway. For other brands looking to seize first-to-market advantage, steps must be taken to reduce lead times and speed up the process through which garments are designed, prototyped, promoted, and delivered to the consumer.

Firstly, procurement leaders must encourage collaborative working between in-house and external teams, ensuring that quality control professionals, creatives and executives with decision-making power are on site with suppliers to facilitate timely product development. In addition, retailers should examine the potential for innovative technologies such as 3D and digital printing to be used in the prototyping process. Aside from this, re-examining the firm‘s logistics provision will also prove useful in further squeezing lead times and gaining vital market share from competitors.

It seems inevitable that the ‘see now, buy now‘ model will redefine supply and demand for retailers, putting high street brands under pressure to react to catwalk tren

RELATED STORIES